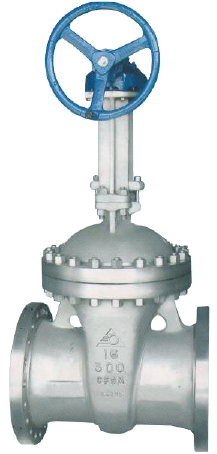

DESIGN

Alphacon Cast Steel Gate Valve are designed to conform to API 600, ISO 10434, BS 1414 and ASME B16.34

Wall Thickness : API 600, API 6D

Face To Face : ASME 16.10, BS 2080, and ISO 5752

Flange End : ASME B16.5 for 2" – 24"

ASME

B16.47 series A or B for 26" and larger

BW End : ASME

B16.25

Inspection & Test : API 598, BS EN 12266, API 6D

CASTINGS

All castings for valve productions are manufactured in our own foundry facility. Raw materials purchased are

carefully inspected before proceed to production to ensure conforms to the standard & required specifications that

meet ASTM, JIS, BS, DIN, etc.

BODIES

Bodies are designed to provide a minimum pressure drop and have a sufficient wall thickness to withstand the

torsion forces and stresses normally encountered in piping systems and to compensate for erosion and corrosion

effects.

BONNETS

Bonnets are designed in various types to meet the valve body & operational requirements and connections are either

flat face, groove for gasket, ring joint faces. Pressure Seal Bonnet available for Class 900 / 1500 / 2500.

DISC / GATE / WEDGE

All the gate has tapered H cross-section and are fully guided to the seats. Solid Flexible gate is cast or

machined with circumferential groove to allow the seating surface to move independently and adjust movement of the

body seats.

SEATS

Integral seats or Forged steel seat is machined and surface is overlay with hard alloy specified by the customer.

Seat is either threaded or welded onto valve body.

BACK SEAT

All our gate valve have the back seating design and is renewable. For stainless steel gate valve, the back seat is

integral.

STEMS

Stems are made in one piece forging with T-head and precision ACME Threads.

STEM NUTS

The stem nut arrangement and design allows for the removal of handwheel at the open position and will not drop

into close position. Thrust Bearings are provided in the stem nut arrangement for large size valves.

GASKETS

Class 150 : Jacketed Graphite with Stainless Steel

Class 300 / 600 : Spiral Wound Graphite with Stainless Steel

Class 900 : Ring Joint Metal

Other gasket materials are also available and are selected generally according to application pressure &

temperature.

GLAND PACKINGS

Die-formed graphoil with braided graphite yarn with corrosion inhibitor is standard materials, other special

materials are also available optionally.

GLANDS

Gland has two-piece construction for easy alignment.

OPERATORS

Gate valves are generally supplied with Hand Wheel operator, having "Open" & "Close" identification. Gear

Operator, Electric Motor Actuator or Cylinder Actuator for remote operation are available on request.

STUFFING BOX

Minimum 125RMS surface finish, cylindricity and vertically precission controlled according to Alphacon design and manufactured standards.